Striving to promote scientific and technological progress and innovation is the part of implementing the "strengthening science and technology" action in Jinchang, Gansu province.

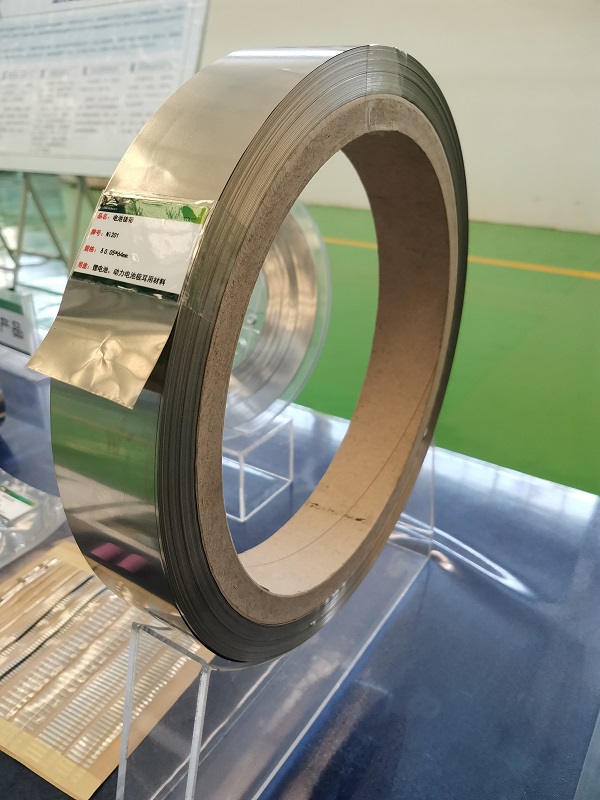

From hand-tearable nickel strips with a thickness of only 0.03 millimeters to carbonyl nickel with an annual output of over 6,800 tons, Jinchuan Group has achieved a ranking among the world's top 500 enterprises. This accomplishment is a result of Jinchuan Group's in-depth implementation of its innovation-driven development strategy, accelerating the transformation of development methods, and continuously improving the independent innovation ability and competitiveness of the enterprise.

Hand-tearable nickel strips with a thickness of only 0.03 millimeters [Photo provided to en.jnmc.com]

Accelerating the promotion of modern industrialization is the inevitable path of domestic high-quality development and an important task in realizing the goal of 14th Five-Year Plan (2021-25).

On the production line of Jinchuan Group Precision Copper Material Co., Ltd., the ultra thick copper nickel alloy pipe with a diameter of 419mm and a thickness of 9mm has become the largest-diameter and thickest seamless copper nickel alloy pipe on the international market. The product has good resistance to seawater erosion, corrosion, and pollution, and is mainly used in aircraft carriers, ships, and offshore drilling platforms.

With its accumulated technical research and development experience and rapid response ability, Jinchuan Group quickly seized the market for thick copper nickel alloy pipes, providing both a domestic supply and meeting the international market demand for the products, which have been sold to shipping and marine engineering companies in Europe, North America and South America, seeing Jinchuan become the preferred partner of shipbuilding enterprises.

The end product workshop of Jinchuan's nickel smelter [Photo provided to en.jnmc.com]

"The successful research and development of the product is conducive to consolidating China's leading position in the global shipbuilding industry, meeting the needs of the international market, while also improving Jinchuan's competitiveness in the global market," said Wang Yanfeng, deputy general manager of Jinchuan Group Precision Copper Material.

The systematic, accurate, and intelligent transformation and upgrading of the traditional mainstream production lines of Jinchuan Group has been injecting new impetus into the company, which has a history of over 60 years. Remotely monitoring the grinding and flotation of production lines, the unmanned intelligent operation of loading and, and the intelligent operation of unmanned driving are no longer scenarios to be imagined, but actual achievements on the production site of Jinchuan's "smart factory".