Lenze in Lin-gang resumes production with a windfall

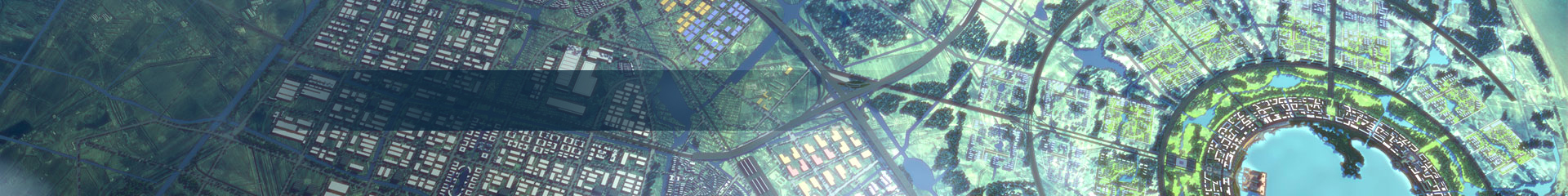

A worker at Lenze Shanghai inspects a machine. [Photo by Hu Xingyang]

The Shanghai arm of Lenze, a famous German mechanical automation company, has restored 90 percent of its production capacity, with 98 percent of employees returning to work.

Several weeks ago, the company was struggling with fragmented supply chains and labor shortages.

Lenze Shanghai mainly produces two kinds of products - mechanical products with high localization, such as electronic gear boxes, and electronic products whose components are still more dependent on German suppliers.

"About 30 percent of supplies are from Germany, but Deutsche Lufthansa AG (Lufthansa) has stopped flights between China and Germany. Air transport was disrupted, and so was sea transport," said Li Chenghong, vice president of operations and R&D of Lenze Asia.

European rail is now the only option for the company.

"However, we were surprised to find trains are actually an ideal alternative," Li said.

Air transport is fast but expansive, while sea transport is cheap but time-consuming. Rail transport is the best of both worlds.

Every Friday, a train carrying parts for Lenze departs from Germany. Although it takes several weeks to arrive, it is very reliable, according to Li.

"It is estimated that the use of the new transport channel has helped us save more than five percent on logistics costs, which is really a windfall during the epidemic," said Wang Xuejing, strategic marketing director of Lenze Asia.

When the company first resumed work, it was operating at only about 30 percent capacity. In order to deliver in time, the company adopted a three-shift schedule (workers are divided into three shifts, namely the morning shift, the afternoon shift and the night shift, according to production needs).

Li Chenghong said that the three-shift system requires a lot of workers, but it was difficult to find enough in an already tight February. With the help of the "Lin-gang Special Area shared employee" service platform built by the Lin-gang Special Area Administration and emergency recruitment, the company has been able to scrape together enough manpower.

"We are still recruiting every day," said Wang Xuejing, "We will be able to make up for the delayed process in May."

- Address No 200 Shengang Avenue, Pudong New Area, Shanghai, China

- Zip Code 201306

- TEL +86-21-68283063

- FAX +86-21-68283000