China's first integrated power generation and storage electric tensioner successfully piloted

China's first electric tensioner that integrates power generation and storage is successfully applied on June 13 at the Weiheyuan 330 kV line project in Dingxi, Gansu. [Photo provided to gogansu.com]

A groundbreaking event occurred with the successful implementation of China's first integrated power generation and storage electric tensioner, as part of the 330kV Weiheyuan transmission line project in Dingxi, Gansu. This innovative electric tensioner signifies a remarkable advancement in power grid construction equipment, ushering in a new era of electrification and sustainability in the industry. The event took place on June 13 in Jinggu town, Kangle county, Linxia Hui autonomous prefecture, Gansu province.

The tensioner holds a pivotal role as a critical mechanical component in power grid construction, working in conjunction with the puller to provide traction and tension for the conductors, thereby enabling the installation of wires. Setting itself apart from traditional hydraulic tensioners, the electric tensioner offers heightened tension control sensitivity at the millisecond level and diminishes tension control deviation to a mere 1 percent, resulting in greater precision in tension control for stringing and a marked improvement in construction efficiency.

Bai Haowei, a member of the research team from the Gansu Electric Power Transmission and Transformation Company, explained, "Our developed electric tensioner generates and efficiently stores electricity during operation, thereby recovering and utilizing traction energy. It operates without the need for fuel or external charging, achieving an integrated cycle of energy generation, storage, and utilization."

On-site data attests to the device's remarkable energy recovery rate of 65.5 percent, leading to savings of 22.8 liters of diesel per hour and a reduction of carbon dioxide emissions by 59.7 kilograms per hour. Moreover, the adoption of this green technology has resulted in a significant reduction in construction noise, from over 70 decibels using traditional equipment to below 30 decibels.

The ongoing enhancements and advancements in tensioning equipment constitute essential endeavors for the future progression of intelligent and sustainable power grid construction. The State Grid Gansu Electric Power Company remains committed to developing standardized mobile battery packs and a suite of electric-driven construction equipment, thereby opening the way for viable core technical pathways for comprehensive electrification replacement and the comprehensive advancement of the equipment industry chain in power transmission line construction.

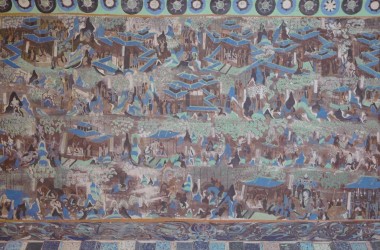

Appreciate Dunhuang Online (XXXIX)

Appreciate Dunhuang Online (XXXIX)

>

>