Development Strategies of Bio-diesel Industry and Policy Options

Aug 12,2008

Li Zhijun, Management World

Research Report No 24, 2008

Biological diesel (bio-diesel), referring to the clean and renewable liquid fuel used by diesel engines, can be extracted from two kinds of raw materials. The first group includes oil plants like rapeseeds and soybeans, oil tree fruits like Jatropha curcas, as well as the aquatic oil plants, such as algae. The second group includes animal grease and waste edible oil, etc. As a good substitution of petroleum diesel (petrol-diesel), bio-diesel is reputed as green diesel. Compared with traditional diesel, it is environment-friendly, and can reduce sulfide pollutant emissions by 70%. Considering its raw materials, bio-diesel is renewable, and enjoys safer transportation, storage as well as usage. The blending of petrol-diesel and bio-diesel according to certain proportions will reduce oil consumption and increase engine power without any modifications to the diesel engine, and will prolong the service life of the engines.

I. Current Status of the Industry and Related Policies

With the supply of traditional fuels like petroleum decreasing, bio-diesel industry gradually obtains greater attention from the central government and numerous enterprises. Since the National Development and Reform Commission (NDRC) of the State Council started to promote bio-diesel industry under the instruction of the State Council in 2002, the Ministry of Science and Technology (MOST), NDRC, and National Natural Science Foundation of China (NSFC) have all extended great support to this emerging industry, and several major petroleum groups in China also participated in this project. An industry foundation with private companies, foreign companies, and state-owned-enterprises (SOE) involved has taken initial shape.

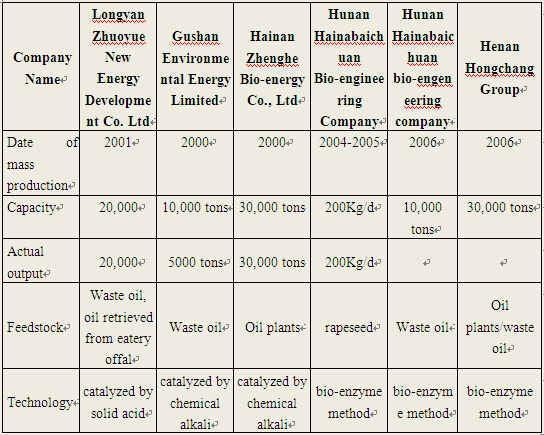

Bio-diesel feedstocks in China are predominated by waste oil from eatery offal, wild oil plants, and waste plant oil, etc. There are dozens of companies in China producing bio-diesel, with an annual capacity of 3 million tons, and an annual output of 300 thousand tons (please refer to the table below). They already have the ability to compete with traditional diesel producers and even make profits without tax reduction and government subsidy.

Right now, PetroChina, Sinopec, China National Offshore Oil (CNOOC), and COFCO have all set up research institutions for bio-diesel. PetroChina has signed a cooperation contract with the State Forestry Administration and Yunnan Province to plant Jatropha curcas in southwest China as feedstocks for bio-diesel production. In September 2006, CNOOC signed contracts to develop bio-diesel industry and invested RMB2.347billion yuan to build a bio-diesel manufacturing base with a production capacity of 100 thousand tons in Panzhihua, Sichuan, with Jatropha curcas as feedstock.

Production Status of Some Bio-diesel Manufacturers

Regarding the feedstocks and techniques of bio-diesel production, several universities and institutes, including the University of Science and Technology of China, the Research Institute of Petroleum Processing, Beijing University of Chemical Technology, Northwest Agriculture & Forestry University, East China University of Science and Technology, Northeast Forestry University, Chinese Academy of Sciences, Sichuan Univeristy and Hunan Forestry Research Institute have carried out studies and experiments on the properties of Jatropha Curcas, Cornus Wilsoniana Wanaer, and Euphorbia tirucalli, and bio-diesel production technologies. Since 2002, the Forestry R&D Center of Chinese Academy of Forestry has carried out a nationwide survey on plants for fuel oil, then analyzed the regional distribution and selected best categories of seed. Layout of a seed breeding base has been designed and industrialization of seed breeding has started.

The central government has attacheed great importance to bio-diesel industry and has formulated related policies to support its development. In 2004, MOST launched the bio-diesel project as a key technology research and development program in the Tenth Five-Year Plan. On February 28, 2005, the Tenth National People's Congress approved the Law of Renewable Energy Resources of China, which stipulates that bio-diesel must be developed. Meanwhile, NDRC listed "key technologies in bio-diesel production and process control" as one of the key technologies to save energy and substitute petroleum. On September 30, 2006, the Ministry of Finance, NDRC, the Ministry of Agriculture, the National Bureau of Taxes and the State Forestry Administration issued the document called "Implementation Opinions about Extending Financial and Taxation Support to Develop Bio-energy and Bio-chemistry", among which bio-diesel is also included. These laws, policies and methods have provided strong guarantee to the steady progress of bio-diesel industry.

II. Major Problems

Bio-diesel industry started late in China due to the lack of strategic planning and government investment. It is still in its initial stage, and we have a long way to go before getting benefits from large-scale development. However, we could already see some positive factors in this industry, such as market-orientation, multi-investment, and increase in farmers' income. However, currently there are some urgent problems to be solved, including the supply of raw material, quality standards, and the immature market.

1. Constraint of raw materials

Supply of raw material has always been a bottleneck to the growth of bio-diesel industry in China. To date, production capacity of bio-diesel in China is over 3 million tons, but due to short supply of raw materials, actual output can only reach 300 thousand tons. Utilization of capacity of bio-diesel manufacturers is quite low. Raw materials in China for bio-diesel are predominated by oil retrieved from eatery offal and acid oil, and only enterprises that have enough supply can survive. The emergence of bio-diesel industry has resulted in greater need of oil retrieved from eatery offal, and in some areas, such oil is purchased in a rush or stocked up, causing rocketing prices. Meanwhile, no efficient organizational system has been established, so only a small part of waste oil has been used. Besides, though a number of Pistacia chinensis trees are planted in some regions, they are scattered around and the quantity is too small to support large scale production of bio-diesel. However, what should be noticed is that some developed countries are making use of the land resources of China to grow oil plants and produce bio-diesel for export.

2. Backward equipment

In order to adapt to complex feedstocks, bio-diesel manufacturing techniques in China has strong adaptability to feedstocks. Right now, industrial technologies used in China mainly adopt waste grease and wild plant seeds as feedstocks, with normal and changed acid and alkali, and solid molecuar sieves as catalyzer. Meanwhile, advanced new technology with enzyme as catalyzer and supercritical non-catalyzer is also under study. Manufacturing technologies in China are quite mature, but equipments are obsolete, and there might be safety problems in manufacturing and operation. Technology standards as well as product examination and inspection system haven't been established, and the technological service system to support the industry has not been formed.

…

If you need the full text, please leave a message on the website.